Fastest and Easiest Way

to Program Robots

Explore solutions that incorporate advanced vision and motion planning technologies

Step 1

Digitize Workpiece

Step 2

Auto-Generate Toolpaths

Step 3

Deploy Adaptive Motion

Deploy adaptive robot motion with a closed-loop system, correcting part deviations for precise execution.

Step 1

Digitize Workpiece

Step 2

Auto-Generate Toolpaths

Generate optimized robot toolpaths and simulate robot motion before deployment.

Step 3

Deploy Adaptive Motion

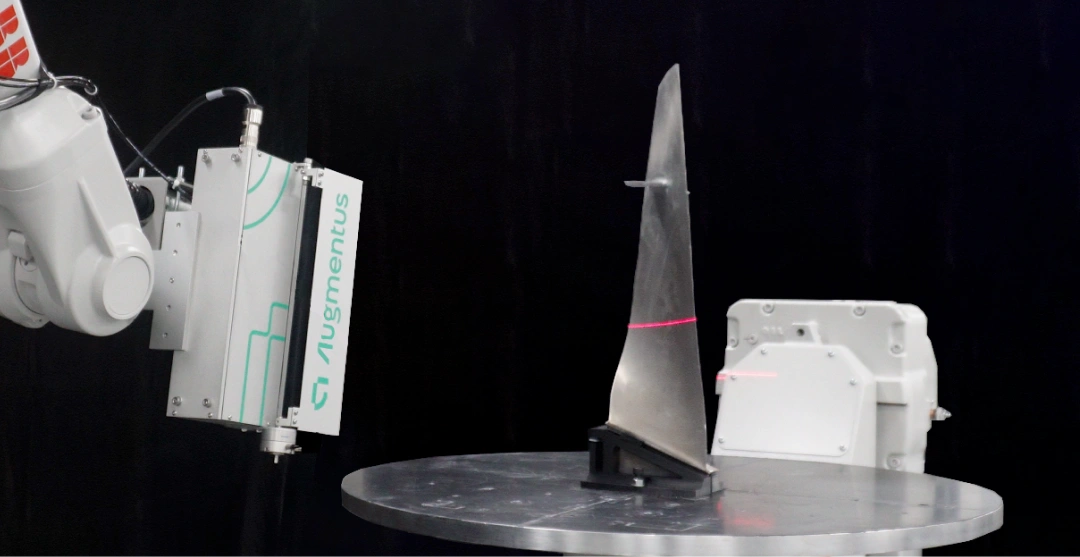

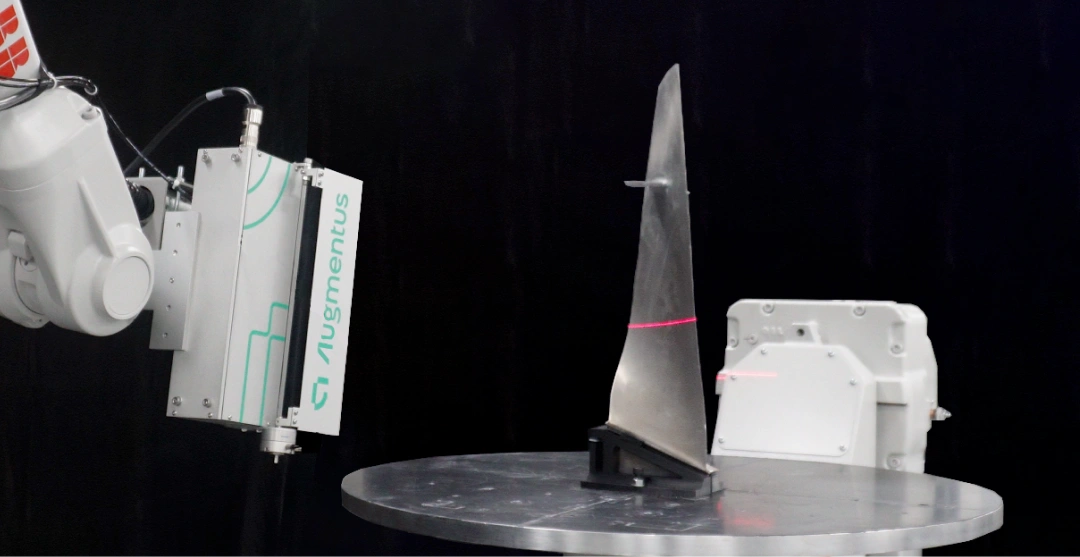

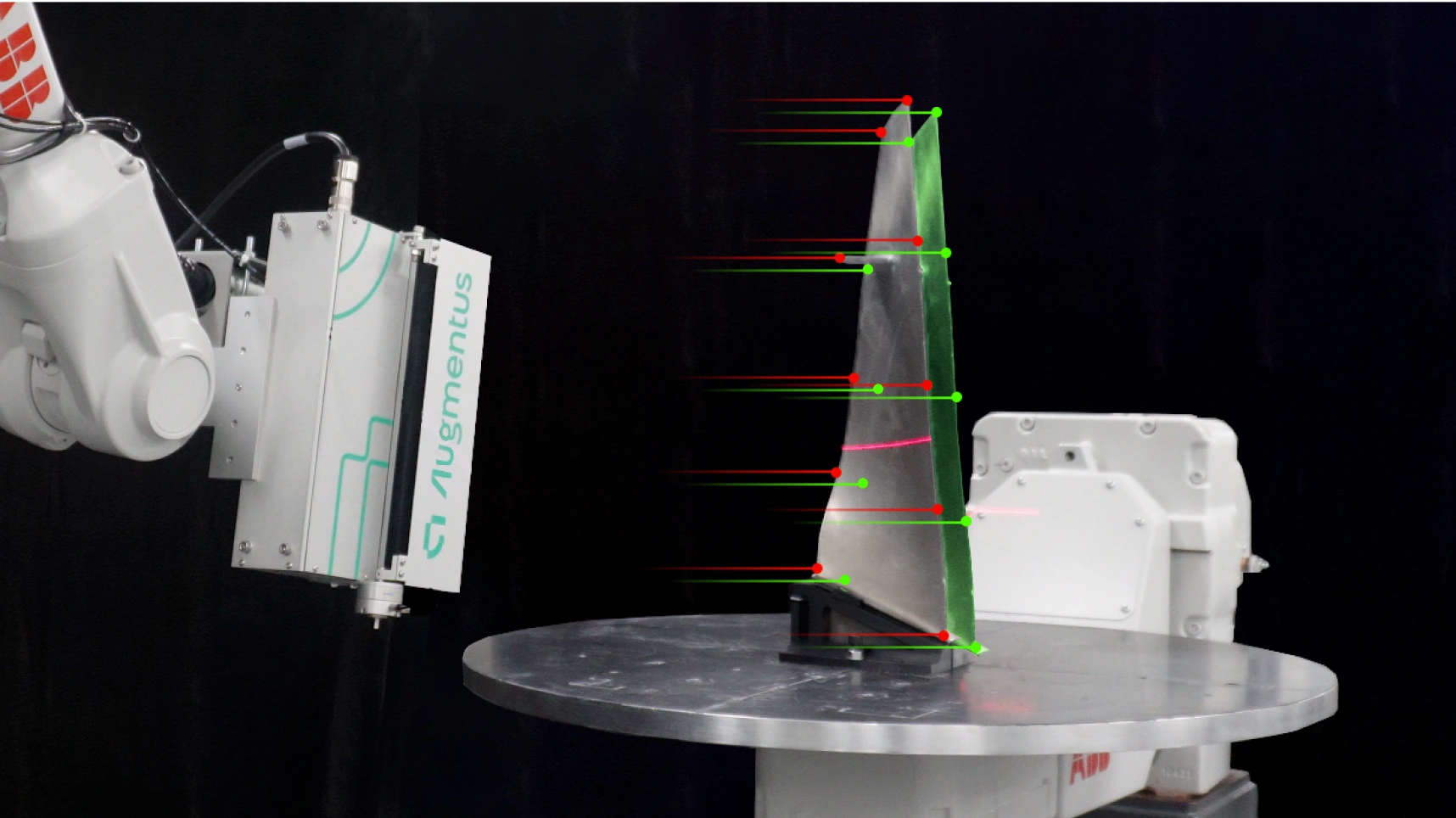

Precise and Rapid Set-Up and 3D Reconstruction

Advanced 3D Reconstruction

Automated Part Localization

Advanced 3D Reconstruction

Augmentus Vision reconstructs parts with high accuracy, generating a digital twin of the workpiece and eliminating the need for CAD files and manual post-processing.

Automated Part Localization

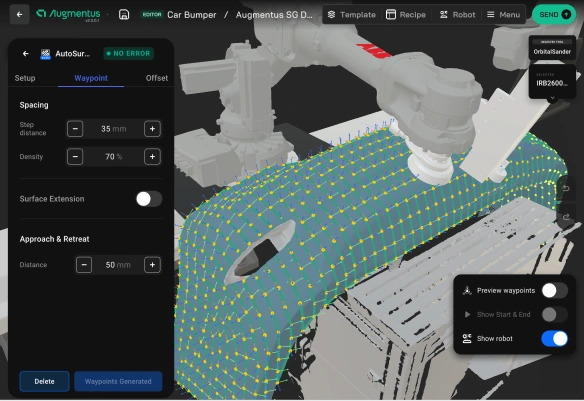

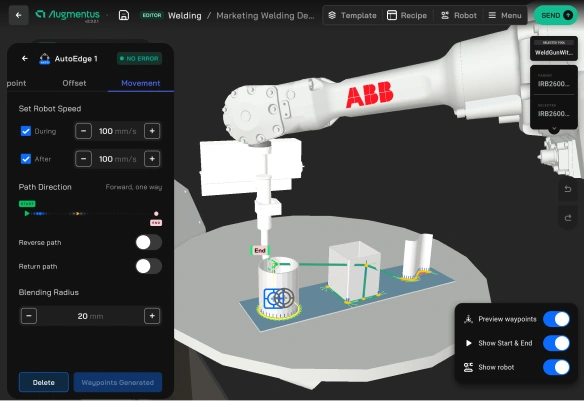

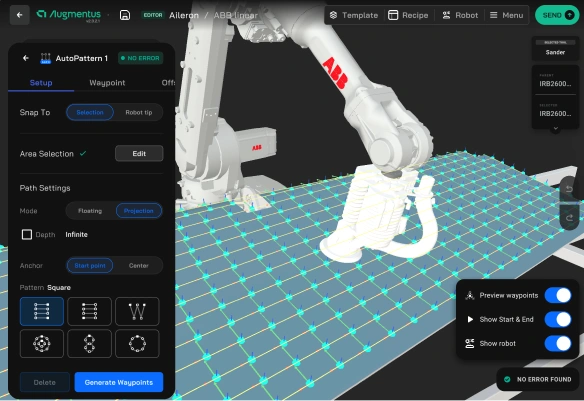

Auto-Generate Complex Toolpaths

Automate toolpath generation for diverse geometries, ensuring precision in robotic processes

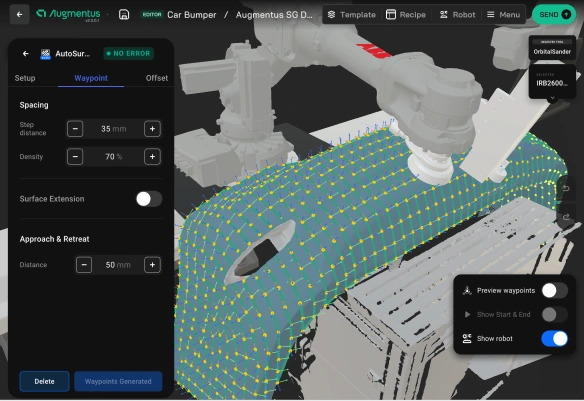

For Complex Shapes

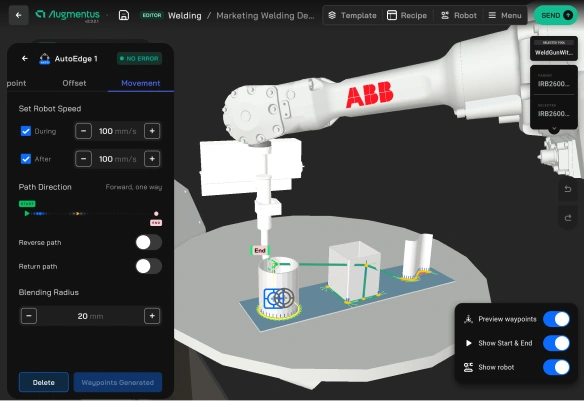

For Challenging Edges

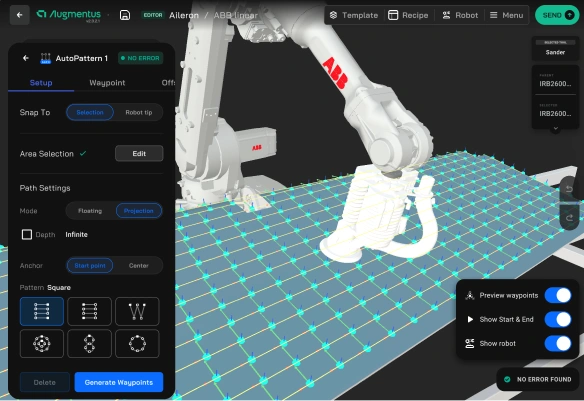

For Predefined Motion Patterns

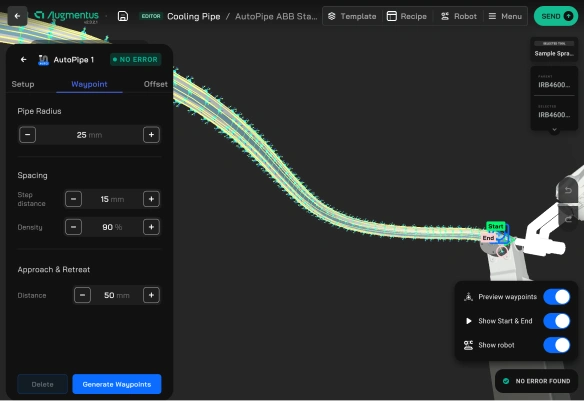

For Cylindrical Objects

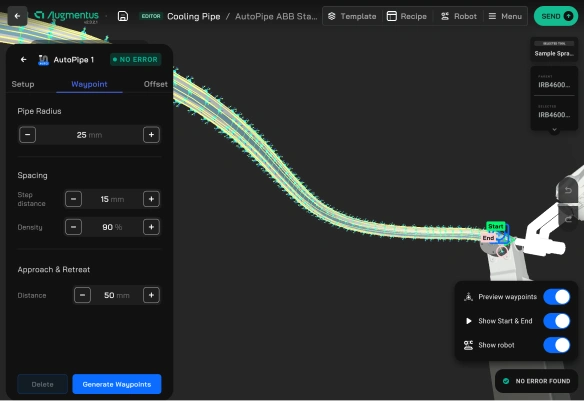

Automates path generation for cylindrical or pipe-like objects with precise curvature and alignment.

For Complex Shapes

For Challenging Edges

For Predefined Motion Patterns

For Cylindrical Objects

Optimize and Simulate Robot Motion

Toolpath Optimization

Offline Simulation

Toolpath Optimization

Offline Simulation

Extended Features

Operator vs Editor Mode

Switch between operation and advanced editing modes.

Template Manager

Save and reuse project templates easily.

Recipe Table

Organize and store process-specific parameters for repeatable tasks.

Custom Tool Integration

Hole Avoidance

Auto-segments holes to ensure accurate motion.

Deploy, Inspect and Correct

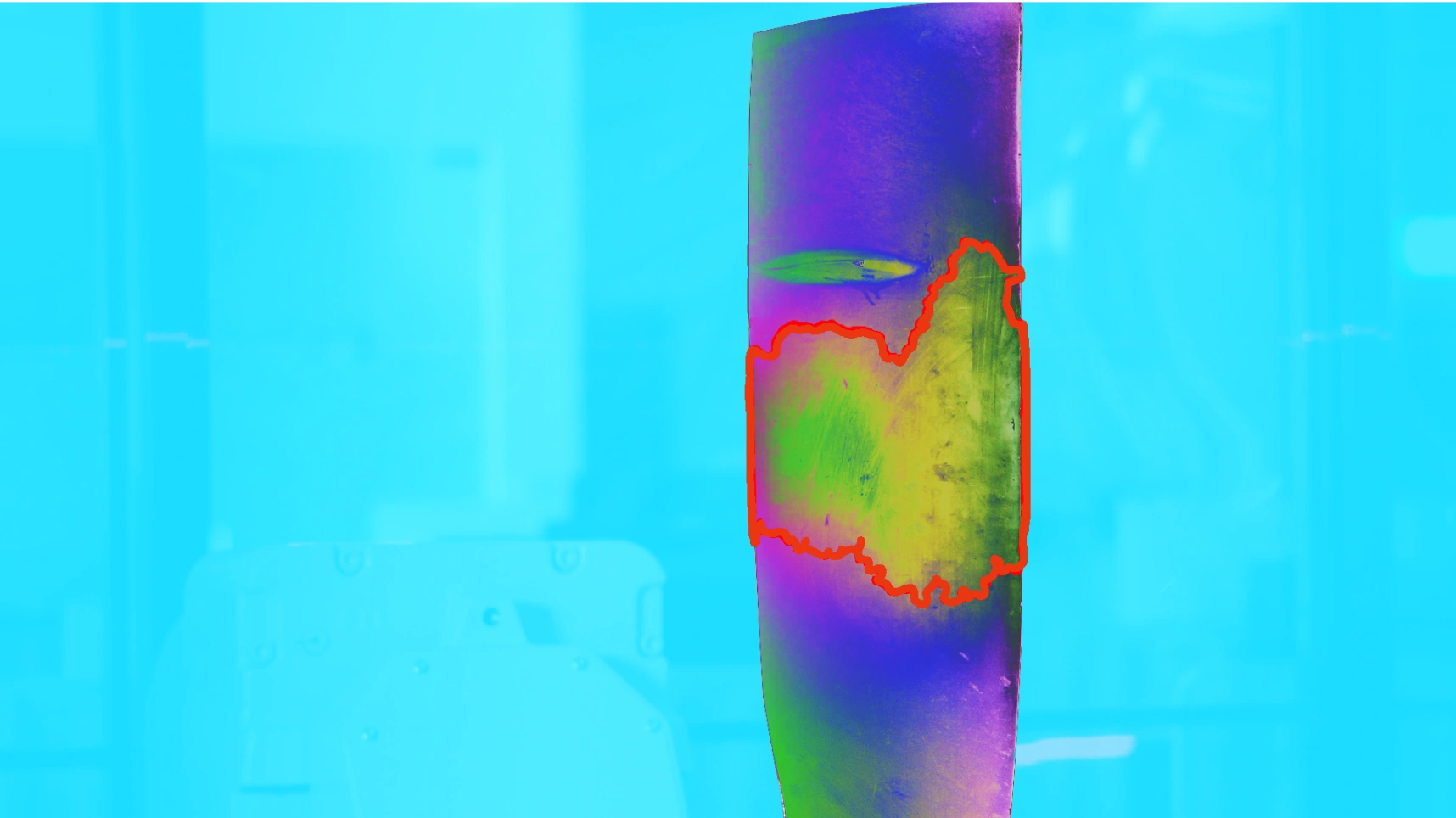

Adaptive Robot Motion

Correct for Part Positional and Rotational Deviation

Augmentus Vision analyzes workpieces to detect positional and rotational deviations, automatically adjusting the robot toolpath to compensate. This capability minimizes the need for precise fixturing while maintaining high accuracy and consistency throughout the process.

Closed-Loop Inspection to Localized Motion Generation

Flexible

2 Days

Retrofit your robot cell quickly with Augmentus

Deep Process Expertise

Tailored deployment with application specialists

Authorized System Integrators Worldwide

Local support through trusted partners

Technical Specifications of Augmentus

Access detailed hardware specifications to ensure compatibility with your automation system setup.

Match Your Needs with the Right Augmentus Solution

Core

AutoPath Software

Pro

AutoPath Software

with Augmentus Vision

Auto

Closed-Loop System

with Adaptive Automation

Core

AutoPath Software

Pro

AutoPath Software

with Augmentus Vision

Auto

Closed-Loop System

with Adaptive Automation

Need Expert Guidance Before Choosing?

Discuss your requirements with our automation experts to find the perfect fit.

Explore Augmentus’ Impact Across Other Applications

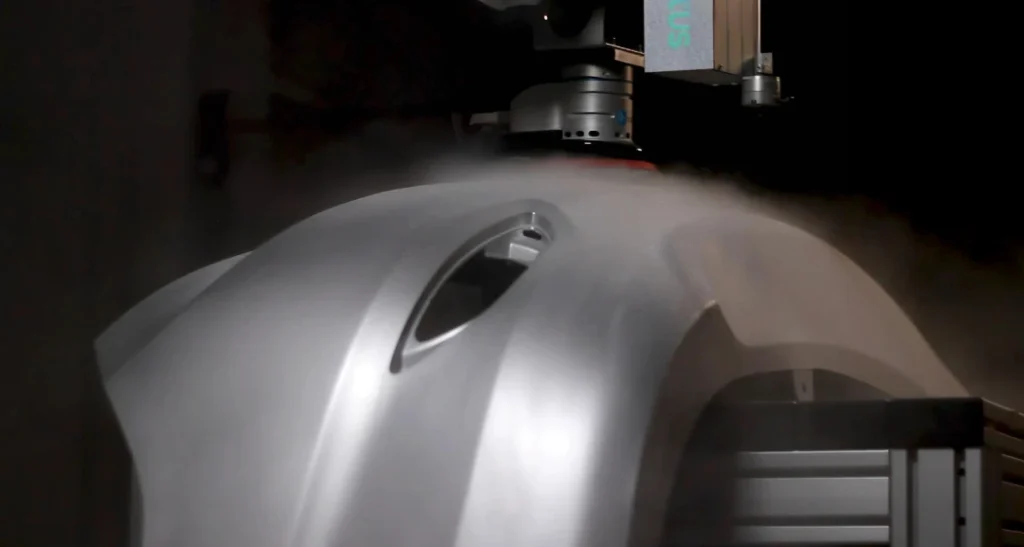

For applications where consistent coating thickness and overspray control are essential, even on complex, contoured surfaces.

For applications requiring uniform contact and pressure on uneven surfaces to achieve a smooth, consistent finish without surface damage.

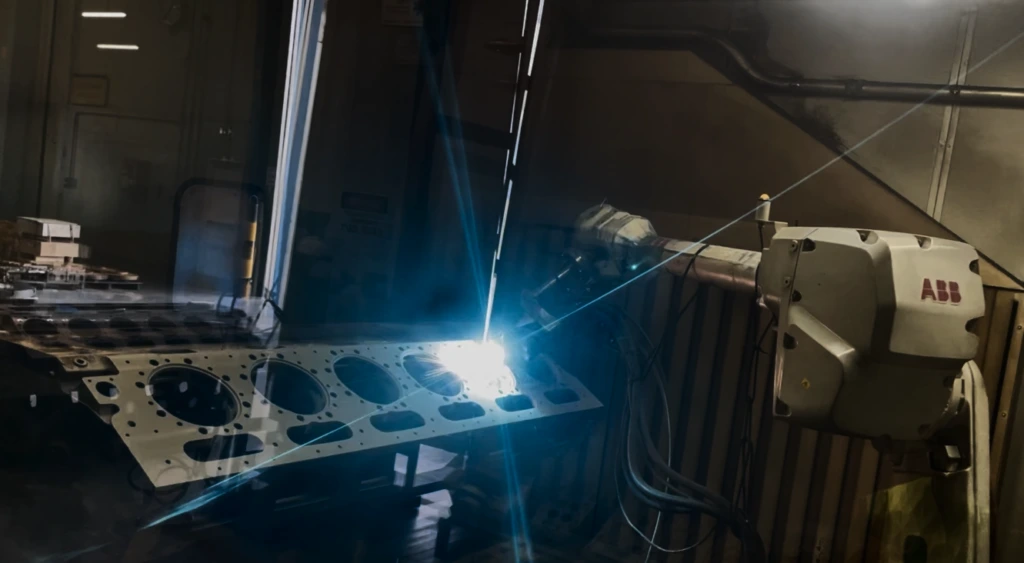

For welding that demands precise torch alignment and controlled speed to produce strong, defect-free welds across various joint types.

For applications where consistent coating thickness and overspray control are essential, even on complex, contoured surfaces.

For welding that demands precise torch alignment and controlled speed to produce strong, defect-free welds across various joint types.