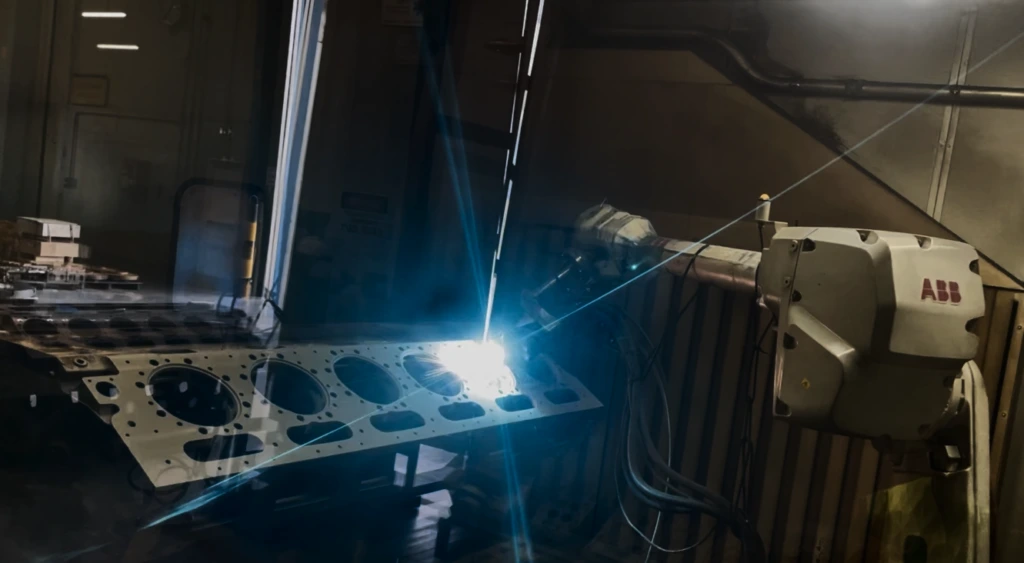

Complex Robot Programming, Simplified

No-code adaptive automation to significantly reduce programming difficulty and downtime

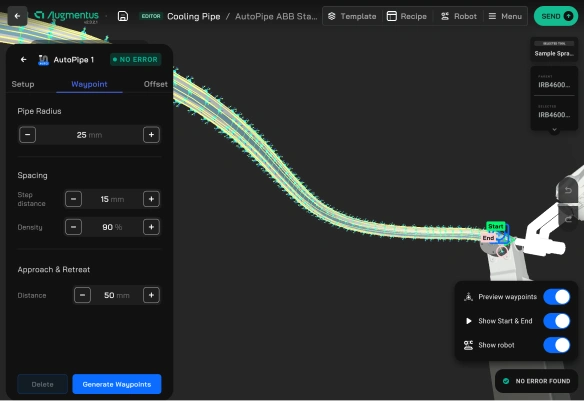

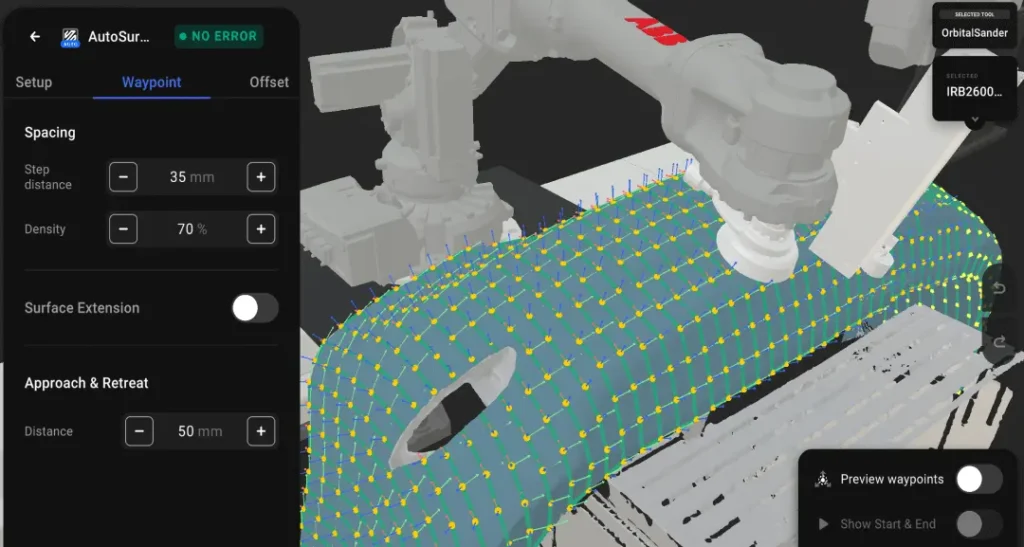

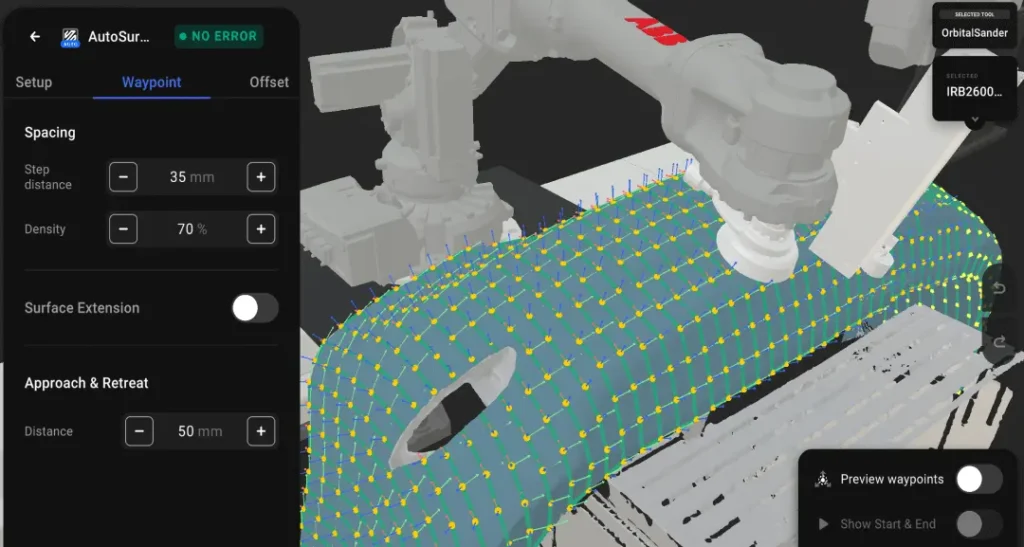

Auto-Generate Complex Toolpaths

Automatically generate complex robot motion with easy control of process parameters (i.e. angle offset, speed, and tool orientation).

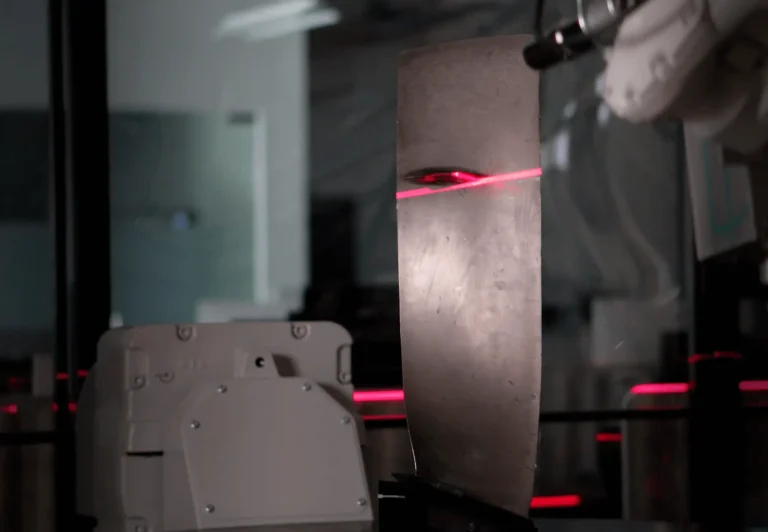

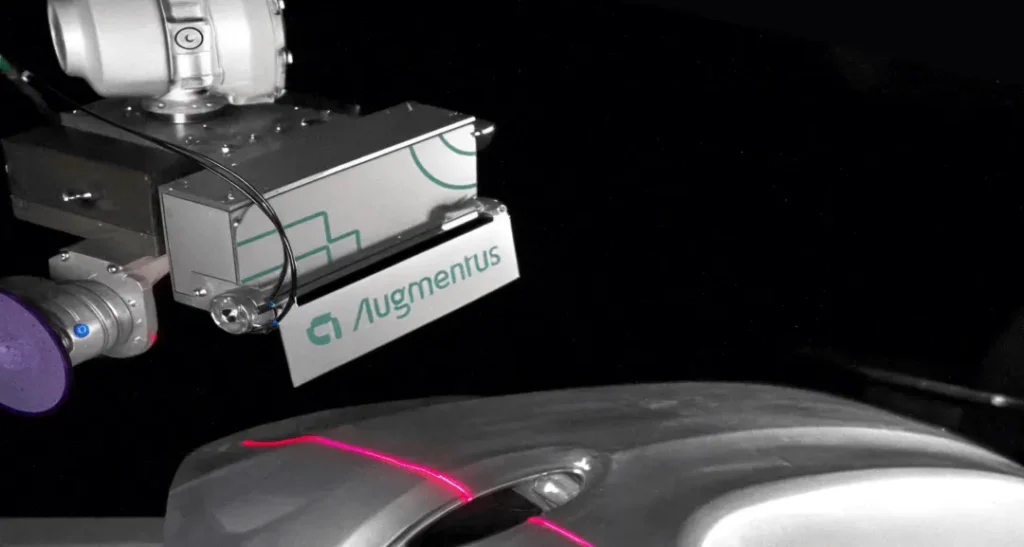

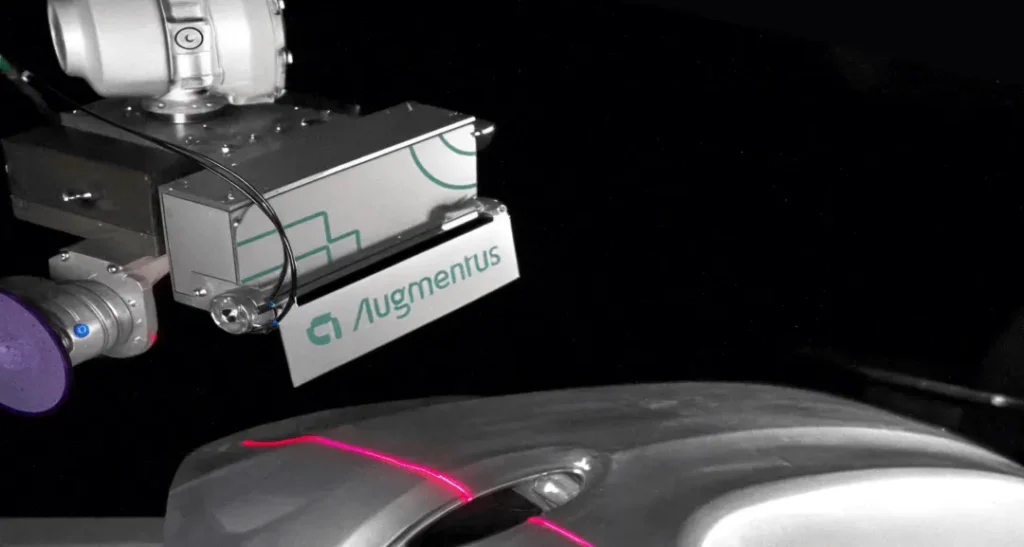

Rapid and Precise 3D Reconstruction

Capture highly accurate 3D scans of workpieces for easy programming of diverse SKUs and geometries.

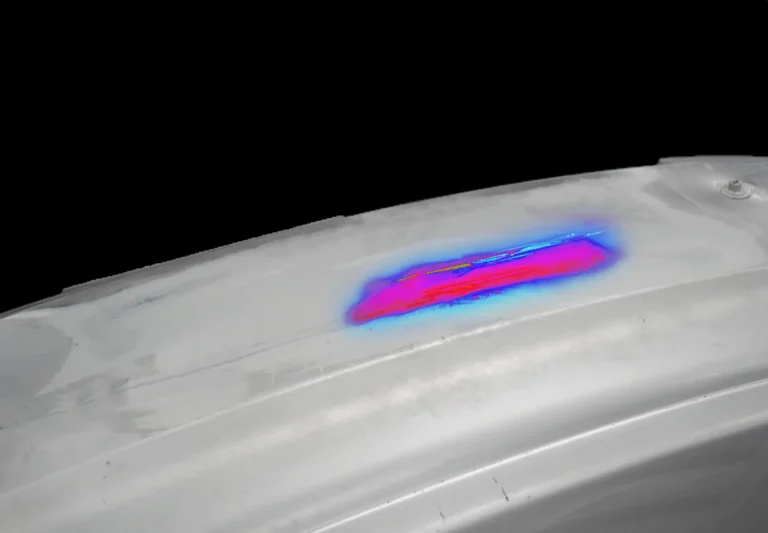

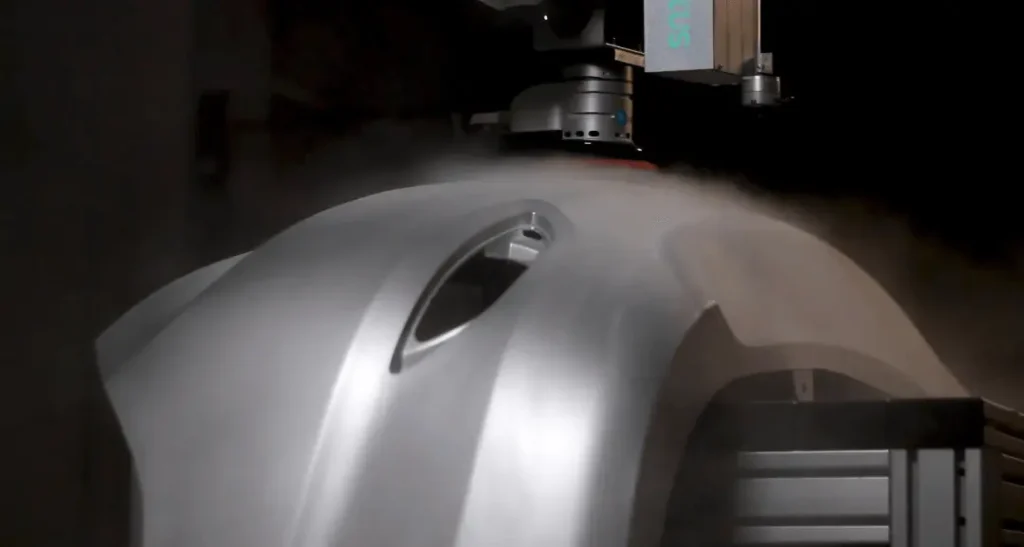

Closed-Loop Adaptive Automation

Auto-Generate Complex Toolpaths

Automatically generate complex robot motion with easy control of process parameters (i.e. angle offset, speed, and tool orientation).

Rapid and Precise 3D Reconstruction

Capture highly accurate 3D scans of workpieces for easy programming of diverse SKUs and geometries.

Closed-Loop Adaptive Automation

Automatically inspect, identify deviations, and generate precise robot motion based on inspection outputs.

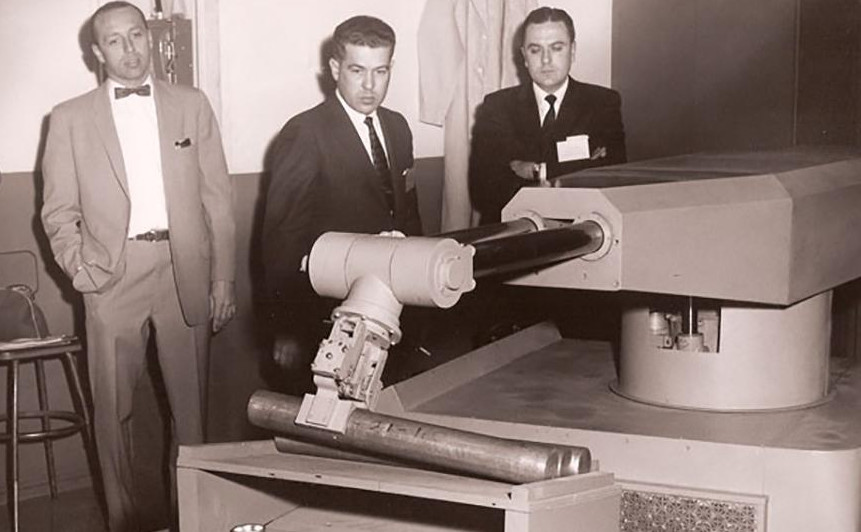

Trusted by Manufacturers Around the World

High-Mix,

High-Variability Manufacturing? Solved.

Minimal Robot Downtime

Intelligent algorithms automatically generate complex robot toolpaths, minimizing robot downtime while enhancing efficiency.

Deviation Detection & Correction

A closed-loop system that automatically detects for part deviations, and corrects robot motion without manual intervention.

Made for Any Operator

Intuitive interface enabling operators to program robots without coding or technical expertise.

3-steps approach to robotic programming

Programming Industrial Robots Has Never Been Easier

Step 1

Scan Workpiece / Import CAD

3D scan parts with high accuracy to map complex shapes and contours for precise robot programming. Alternatively, leverage existing designs by importing CAD files of workpieces.

Step 2

Auto-Generate Toolpaths

Generate and optimize toolpaths, followed by offline simulations to preview motion before deployment.

Step 3

Deploy Adaptive Motion

Deploy adaptive robot motion that identifies part-to-part deviations for precise and consistent execution.

Augmentus advantage

Programming Industrial Robots Is Now Much Easier

Solutions for Various Applications and Industries

APPLICATIONS

INDUSTRIES

Aerospace

Automotive

Brake discs, engine cylinder liners, turbocharger components.

Industrial

Construction

Steel beams, bridge components.

Aerospace

Aircraft fuselage, wing panels.

Automotive

Chassis, wheels.

Energy

Boiler surfaces, heat exchangers.

Industrial

Conveyor systems.

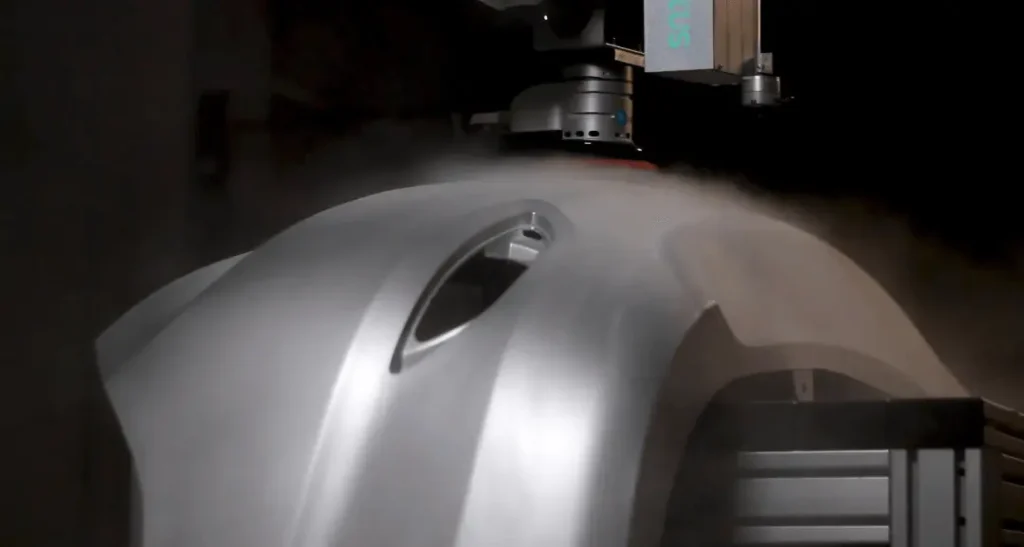

Aerospace

Aircraft exteriors, wing surfaces.

Automotive

Car exteriors, bumpers.

Energy

Turbine exteriors, panel frames.

Consumer Products

Electronic casings, furniture, appliance casings, plastic and metal toys.

Aerospace

Composite panels, interior fittings.

Automotive

Body panels, door edges.

Industrial

Mold surfaces, casting parts.

Consumer Products

Wooden furniture, musical instruments.

Aerospace

Aircraft frames, engine components.

Automotive

Exhaust systems, fuel tanks, car chassis.

Oil & Gas

Structural frames, tank repairs.

Consumer Products

Bicycle frames, metal casing for refrigerators, metal frames for furniture.

Compatible with Major Robot Brands